Let's get loopy

This month, NSW starts phasing out single-use plastic, by prohibiting the supply of lightweight plastic bags. In November, additional items such as single-use plastic straws, cutlery, cotton buds, and polystyrene food service services items will also be banned.

In a world that is addicted to single-use plastic products, this month’s blog looks at why this approach has been enacted, and the expected outcomes of moving towards a circular economy.

Background

The world is choking on plastic. More than half of all the plastic ever produced has been made since 2000. To make matters worse, 50% of all plastic produced is for single-used purposes and less than 9% of plastic gets recycled. Every minute, the equivalent of a garbage truck loaded with plastic ends up in our oceans, and if nothing changes, it is estimated that plastic in the ocean will outweigh fish by 2050.

With that in mind and the fact that Australia has the third-highest material consumption rate in the world, there is no wonder why actions are urgently needed.

That’s why in June last year, NSW Government released the NSW Waste and Sustainable Materials Strategy 2041 which supports the transition towards a circular economy over the next 20 years. In this strategy, NSW Government takes a stand to minimise what we throw away, and to use and reuse our resources efficiently, making them as productive as possible.

Phasing out problematic single-use plastic items is a key reform of this strategy. But how can we create a circular economy for plastic?

The circular economy

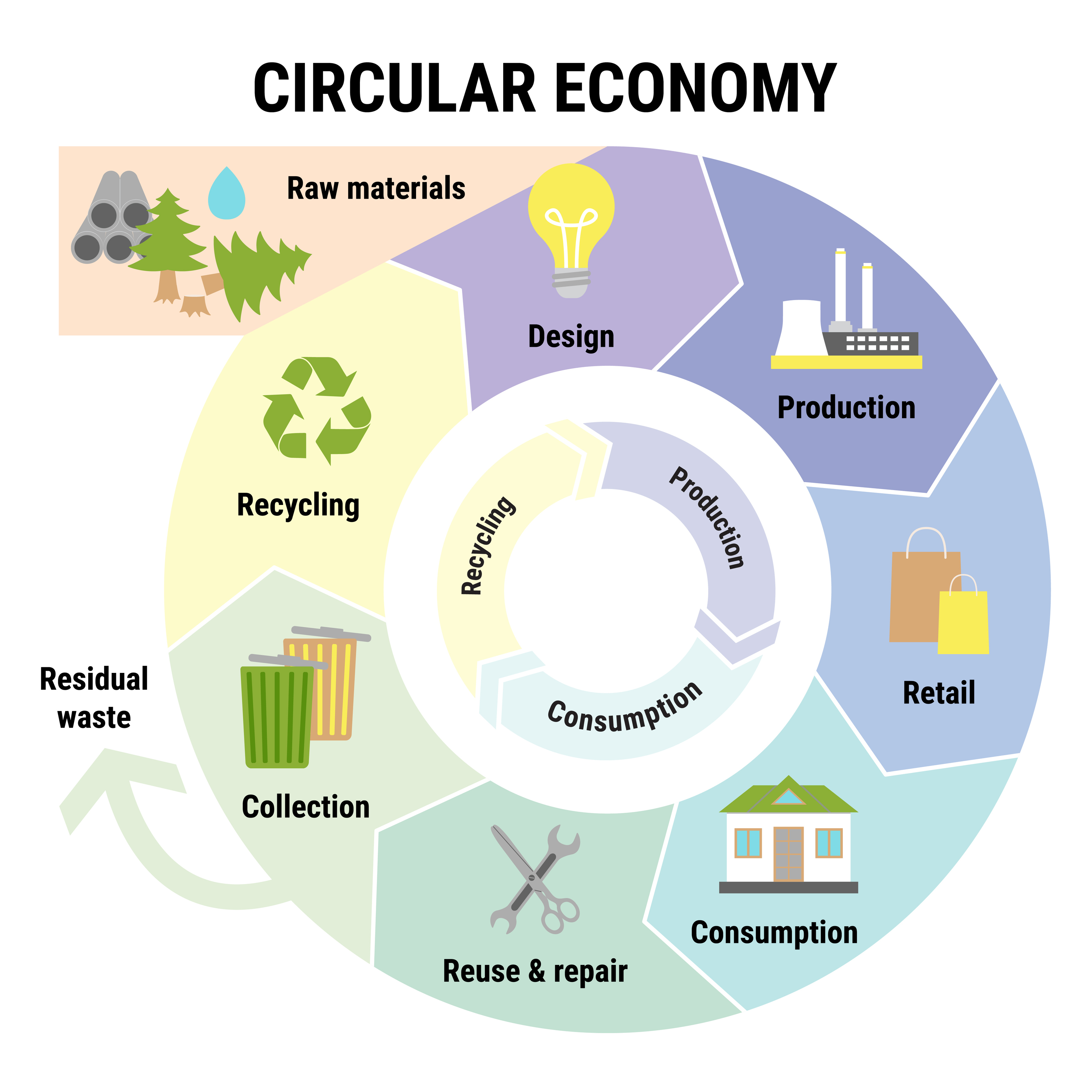

A circular economy is an economic model that is restorative and regenerative by design, and underpinned by three key principles:

- Design out waste and pollution

How can we design with the full cycle of a product in mind so waste is never created, or if it is, it is used as a resource for something else? Can we promote a product-as-a-service model such as Car Next Door or Netflix or we access a service rather than owning a product? - Keep products and materials at their highest value for as long as possible

How can we ensure that materials and products keep flowing in a closed-loop model through various models such as share, reuse, and repair? - Regenerate natural systems

How can we go beyond protecting our environment and start supporting and replenishing it?

The circular economy is often best understood through our current economy where we take materials from the Earth, make products from them, and eventually throw them away as waste – the process is linear. In a circular economy, by contrast, we stop waste from being produced in the first place.

Plastic

First introduced in 1862, during the Great International Exhibition in London, plastic became widely adopted by various industries post World War II. Ever increasing demand means, plastic production has grown twentyfold and is expected to double again in the next 20 years.

The process to make plastics requires a lot of resources. Raw materials like gas, petroleum or plants, are extracted and refined into ethane and propane. Then, ethane and propane are treated with heat in a process called “cracking” which turns them into ethylene and propylene. Finally, these materials are combined to create different polymers, and fashioned into products or packaging.

Disappointingly, most plastic packaging is only used once, with only 14% of it is collected for recycling which means that 86% of it remains in the environment (and our bodies).. in addition Ellen MacArthur Foundation has estimated that 95% of the value of plastic packaging, worth USD 80-120 billion annually, is lost to the economy.

So how can we design an economy where plastic flows in a closed-loop system, and never becomes waste or pollution?

It is time for a circular economy for plastic

To follow the principles of a circular economy, design will have to be rethought and take in consideration the entire life cycle of a product with an important emphasis on reuse, recycling being the very last resort. The process of making plastic itself will have to be streamlined, using less if not only one polymer, making it easier to recycle when the need arises.

Demand for recycled plastic will need to increase around the world. But government incentives and programs will not be sufficient, companies will also need to commit to using more recycling plastic in their production as well as rethink the way they produce and use plastic. And as consumers we play the most important role in shifting our habits and behaviours. Refuse – Reduce – Reduce – Repair, and only then, recycle is a good way to start.

Author: Laura Pigot-Repšys